Sage 300 Manufacturing

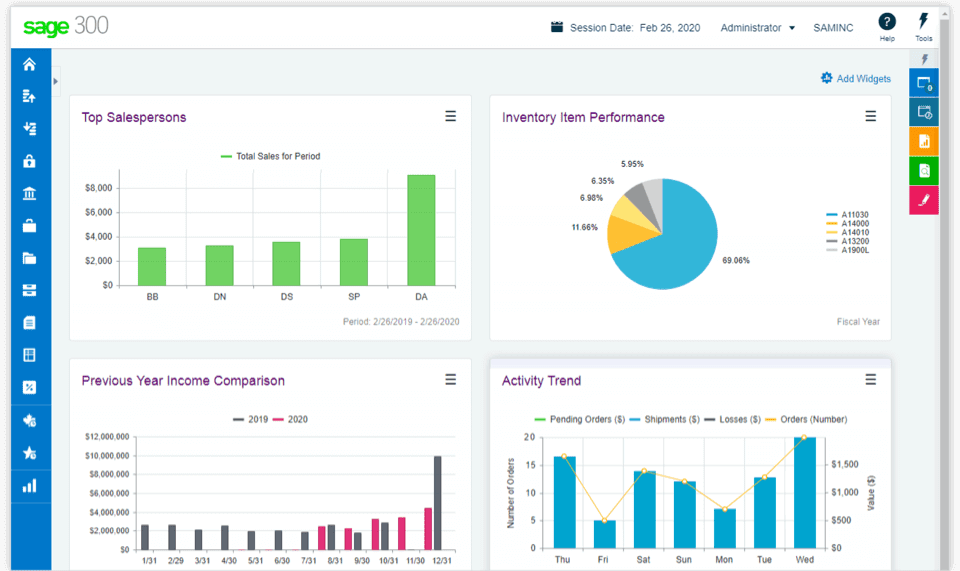

Sage 300 Manufacturing is a comprehensive software solution that is designed to help manufacturing companies streamline their operations and improve their overall efficiency.

Sage 300 Manufacturing Key Features

Increased accuracy of production cost calculation

• Rolled up standard item costing from Sage 300 Inventory Control upon finished goods receipt

• Costs can be based on material and resource requirements, including labor and overhead costs

Easier monitoring of WIP

• Materials issued from 1/C are tracked as WIP

• WIP consumption and scrip transactions trackWIP movement as it happens

• Unconsumed WIP are automatically allocated upon closeout of manufacturing orders

Super-charged BOM structure

• Unlimited number of BOM codes and versions per product

• Up to 16 BOM levels

• Detailed item routing information

• Supports unlimited number of co-products

Operation-based transactions

• Sub-divide production floor into work centers used by BOM operations

• Transactions such as material issuances, WIP consumption, or scrap can be performed by operations

Serialized inventory and lot tracking

• Full support of serial and lot numbers for 1/C items

• Define lot and serial numbers for materials issued, returned, and finish goods received in the warehouse

Backflushing

• Create manufacturing orders, issuances, and receipts in one step for Just-in-Time (JIT) production

Sage 300 Manufacturing Modules

Intercompany Transactions

Create and distribute your transactions across multiple companies with Intercompany Transactions.

Key Features

- Multilevel routes between companies with any number of intermediate companies

- An Intercompany loan account reconciliation report

- Full Multicurrency support and integration with Tax Services

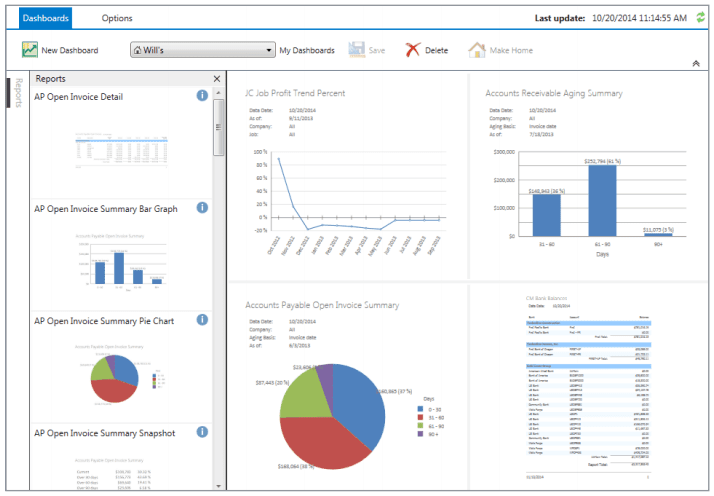

General Ledger Consolidation

Transfer or merge transactions and your General Ledger between multiple companies or branch offices. Designed for holding companies or subsidiaries to manage on different databases or networks, it provides a set of features for defining the level of detail wanted during consolidation as well as a comprehensive audit trail.

Intercompany Transactions

Create and distribute your transactions across multiple companies with Intercompany Transactions.

Key Features

- Multilevel routes between companies with any number of intermediate companies

- An Intercompany loan account reconciliation report

- Full Multicurrency support and integration with Tax Services

More Sage 300 Modules

Sage 300 Distribution

As a distributor, it’s vital for you to seamlessly integrate new suppliers and sourced products into your supply chain. Sage 300 Distribution allows you to streamline warehouse operations, manage pricing and promotion, and more.

Sage 300 Financials

For businesses with numerous entities and locations, Sage 300 provides best-in-class, cloud-enabled financial solutions. It has a multi-currency and multi-language user interface.

Added Benefits of Sage 300 Manufacturing

Better Quality

Enhanced quality is a major outcome of an ERP. It enables applying quality check at all points of the manufacturing. Experience better quality in crucial areas of your organization that help you keep everything running smoothly with visibility.

Cost Reduction

The direct benefits of an ERP are reduced overheads and processing time. Not just this, proper planning through an ERP leads to optimum inventory level and reduced inventory means less wastage, cut-down on space, labor, and more.

Better co-ordination and Extensive Reflectivity

ERP brings together all departments and functions in a manufacturing unit and links them through a centralized database. Everyone from Production Manager, Inventory Manager, Shop-Floor Attender and QC Personnel gets the same version of the truth and also the real-time information.

Improved Efficiency

ERP is designed to automate and support elongated supply chains. Manual processes can be error-prone and time-consuming. Employees may forget certain vital steps in the processing leading to inefficiency. But an ERP can standardize and accelerate procedures on every operation.